Contents

Contents

By the late 18th century, artillerymen were considered elite troops. In an age of widespread illiteracy, soldiers who could do the geometric calculations necessary to place a cannonball on target must have seemed almost as wizards. Indeed, even though for centuries it was known that the flight path of spears and arrows was parabolic, the fellow who demonstrated it mathematically, Galileo, came close to being burned by the Inquisition for his heretical ideas. But mathematical calculations were only a part of the science of artillery, which is worth a web page all to itself, so let’s begin.

Background

The earliest European devices that we would recognize as artillery were called “bombards”, an Old English word which is believed to derive from the Latin “bombus” or deep, loud noise. But “bombard” itself is a trap for the unwary researcher, as the term was also used to describe catapults. Thus, if a historian speaks of a cannon of gigantic dimensions that could hurl projectiles many times the weight of a man, it’s more than likely that he or she has misread an ancient manuscript. I often think that Frank Sinatra and Cary Grant hauling a giant cannon across Spain in “The Pride and the Passion” was the result of just such an erroneous reading of history.

Given the technology of the age, giant cannons would have been prohibitively expensive, and couldn’t possibly withstand the powder charge that would have been required. Or perhaps they could – powder was notoriously unreliable, but that’s another story.

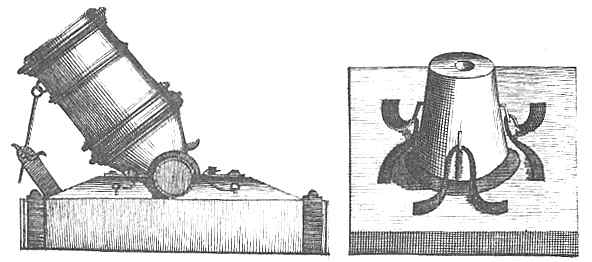

The earliest artillery pieces resembled the much-caricatured witches’ cauldron, except with much thicker sides and a small basin. Indeed, the French dubbed them “pots-de-feu” or “fire pots.” This design, which appeared in the early 15th century, was known in the late 18th century as a “mortar,” from its resemblance to the mortars used for grinding. Hence, they would seem a logical place to begin our study.

Mortars

While initially limited to use in Siege warfare, mortars came in a variety of types and sizes, depending on their intended use.

Larger mortars were of two types, Land or Sea Service, which, like all ordnance of the day, were either of bronze or iron. Land Service mortars were lighter than their equivalent caliber of Sea Service mortar, since they had to be lifted manually on and off carts and into position, whereas the Sea Service mortars were installed in “bomb ketches” and needed no manhandling.

By 1775, there were nine different Land Service and four Sea Service Mortars in the British inventory, ranging from 4.4 inches to 13 inches in caliber. A major difference between the mortar’s design and that of cannon was that mortars were chambered. That is to say, a powder chamber was bored into the breech end of the inside of the tube which was smaller in diameter than the bore of the tube. The powder charge went into the chamber, and the weight of the shell was on the ledge above it. Otherwise, the tremendous weight of the shell would compress the powder, inhibiting ignition, or worse, causing ignition when loading. This design also allowed a constant ratio of air space to powder, which in turn meant mathematical predictability of ballistics from one shot to the next. With mortars, as opposed to other types of artillery, instead of having a fixed charge and varying the elevation of the gun to range the projectile to target, designers used a fixed elevation – 45 degrees – and gunners in the field would vary the charge to reach the target.

The length of mortar barrels were never more than three times the caliber of the gun, and as short as one caliber in large iron guns.

Due to the fixed elevation, the design of mortar carriages was a simple matter; all that was needed was a stout wooden “baulk”, in which a recess took the breech end of the gun and held it at 45 degrees. Trunnions are seen on the breech end of mortars, to spread recoil over a greater area, and not for any change in elevation, as in true cannon.

Sighting was simplicity itself – a line would be scored or painted down the center surface of the barrel, parallel with the central axis of the bore. This would be aligned with the target by use of a plumb line.

The smallest of the mortars in use in the late 18th century was the “Coehorn” a four and two-fifths inch bore size. This was named for the Baron de Coehorn, Director of Artillery of the Dutch Army a century before the Revolution, who had adopted this design. 13 1/4 inches in barrel length, and weighing 84 lbs, the Coehorn could throw an 8 1/2 lb shell 800 yards. It could be moved by a crew of two or three men.

The “Royal” mortar was 5.4 inches caliber, 16 1/2 inches long and weighed 112 pounds. It fired a sixteen pound shell 1000 yards.

The “Stone Mortar” was in service at this time, though never shown on returns of ordnance or on inventories. These were frequently of ad hoc manufacture in the field, followed no “sealed pattern”, and came in any and every caliber. They took their name from their ammunition; sacks or baskets of stones and scrap metal, fired for their nuisance value. The maximum range was some four or five hundred yards at the best of times, and they were generally used by defenders during sieges in order against those digging the attacking trenches. Small calibers of stone mortar could be used to throw the hand grenades of the day, which were merely small bombs thrown by hand, as can be seen caricatured in Mad Magazines’ “Spy vs. Spy” cartoons.

Howitzers

The howitzer was originally developed to fire bombs (powder-filled explosive shells.) This required a large bore in order to get the best effect from the larger projectiles, but it also required that the propelling charge be reduced to about one-ninth of the shell weight, in order not to over-stress the hollow projectile. Since the small charge burned so quickly, there was no need for a long barrel, and the howitzer therefore evolved into a large caliber gun with a short barrel – about five to seven times the caliber was the generally accepted figure, as opposed to 15 to 25 times for guns. Howitzers, like mortars, were chambered.

The advantages of dropping the explosive shell over obstacles was introduced after the howitzer had entered service, and the design was soon modified to allow more elevation to the barrel to obtain plunging fire. Due to the short barrel and light charge this did not introduce any complications in the way of carriage design, although it must be stressed that in the 18th century, an elevation of twenty degrees was considered high for a howitzer. It should also be added that although the elevation was increased over that of the gun, this was offset by the lower charge, and the howitzer never achieved greater ranges than guns of equivalent caliber.

Cannons

The late Chinese leader Mao Zedong, in his “Sayings of Chairman Mao,” observed that all political power proceeds from the barrel of a gun. Ironically, the Chinese, who developed the first forerunners of cannon, left it to Europeans to put them to political use, and hence give us our name for them, as we shall see below.

Saltpeter, the legendary bane of lusty soldiers and primary ingredient in gunpowder, was discovered by Chinese chemists during the Sung dynasty, around AD 900, but used for little more than firecrackers. The most advanced military application was the “fire lance,” a bamboo tube several feet long, wrapped with strong twine to keep it from bursting on ignition of the saltpeter within, and attached to a long handle for holding and aiming. The name came from using small spears as projectiles. The device was ignited by use of a fuse inserted in the muzzle.

Saltpeter came to Italy as “Chinese snow” with Marco Polo, and once gunpowder was developed and married to European metallurgy, cannons soon followed. The word cannon comes from the Latin root canna, or reed (shades of the fire lance!) The word canon (Latin for “statute” or “law”) was used in Italy as early as the 14th century to describe a cannon. “Ordnance” comes from ordinance, a Latin synonym of canon.

Thus, just as Colonel Colt’s invention became the “Peacemaker,” early cannon were equated with the bringing of Law and Order. There was another good reason for this association with authority. We’ve mentioned that the manufacturing of cannon was incredibly expensive, but so was the manufacture of saltpeter and ultimately, gunpowder. Hence, kings were the only ones who could afford the weaponry, so individual knights and warlords eventually became victims of the cost of new technology and were replaced by national armies.

The Chinese, by the way, came to rue letting the cat out of the bag, as during the Ming dynasty, Europeans brought cannon and gunpowder back home to roost, with predictable results.

The cannon used in the Revolution by all armies was the standard smooth-bore muzzle-loading gun which had been little changed in the previous two hundred years and which would serve as the principal artillery weapon of most of the worlds armies for another hundred. They were cast of iron or bronze; loaded with a prepared cartridge of paper or cloth containing gunpowder, followed by a projectile. It was fired by igniting a goose-quill tube containing gunpowder, or “quickmatch,” inserted into a vent-hole that communicated with the charge in the gun; and when fired, the recoil threw it backward, necessitating it being wrestled back into the firing position by the gun crew.

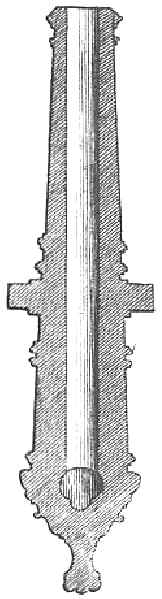

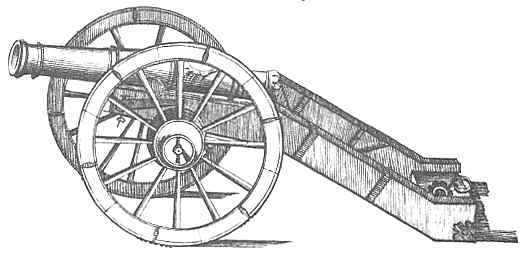

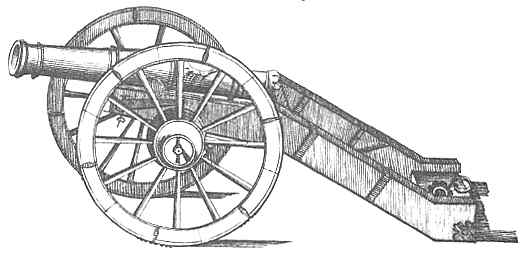

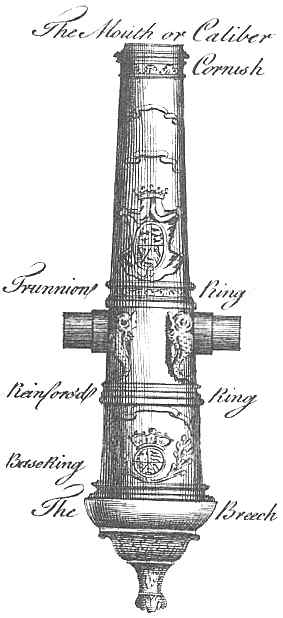

Left, a British 16-pounder, circa 1775, illustrating the different parts. Right, a cut-away view of the same gun. For those who like technical terms, the rearmost protrusion is called a “Cascabel,” used for attaching ropes to hoist the gun in transit. The barrel, as we would call it, was known as the “Chase.” The touch hole would be in the center of the heraldic design which is just forward of the Base Ring. For obvious (I hope) reasons, guns were “preponderated,” meaning that the breech area around the powder chamber contained much more metal than the rest of the gun. This also helped in aiming, as it caused the gun to sit more solidly on the quoins used for elevation..

The main field pieces in the war were the 3-pound galloper and the steady 6-pound field piece.

The American organization of artillery forces followed the European pattern. Except for the light infantry accompanying guns, the establishment was entirely fluid and determined by the requirements of a particular campaign. The “Batallion Guns,” which were more or less permanently attached to the infantry, were based on an idea of Frederick the Great, though instead of being hand-drawn they were modified into horse-drawn “galloper guns,” three and four-pounders drawn by two horses in tandem.

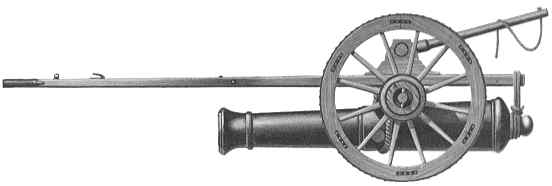

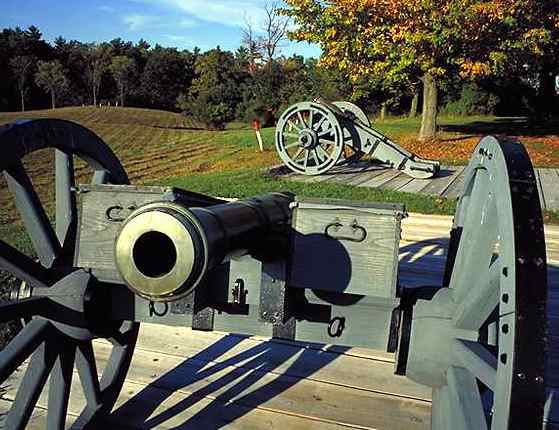

Above is an American 4-pounder galloper. Gallopers were among the first attempts to give some degree of mobility to guns, which had been, for centuries, a stationary weapon. The “improvement” looked better on paper than in the real world. The term “galloper” evokes images of a lightning descent onto the battlefield, a crashing volley of decisive effect, and a rapid gallop off to some other threatened point, but alas, the reality was somewhat different, since although the gun was rapidly portable, gun crews were still afoot, and the ammunition trundled along behind in ox-carts.

The swivel gun was a small cannon named for its mechanism of attachment. It was about the only 18th-century gun that was not a “crew-served” weapon, although its effectiveness was multiplied when manned by more than the gunner. Once mounted, almost always on a fixed base (as the block of wood shown below) it may be pointed quickly to any quarter. But the swivel mechanism cannot stand heavy recoil, so the size, and hence effectiveness, of a swivel gun is severely limited.

Projectiles

Cannon calibers became relatively standardized during the 1600s based on the weight of the ball projectile used in the gun. The smallest standard cannon was the two-pounder, and the largest was the fifty-pounder.

The range of projectile design was probably more diverse in the 18th century than it is today. The standard was, as you probably already guessed, the cannonball. This was simply a cast-iron sphere. High school physics tells us its effectiveness derived from its mass times its velocity. And the greater the range, the less the effectiveness, except for rolling and bouncing haphazardly enough that enemy personnel would be doing a jig to avoid it. In “Private Yankee Doodle”, Joseph Plumb Martin relates a story of American soldiers running across a muddy parade ground to retrieve British cannonballs when their own gunners were short on ammunition, with a ration of rum as the reward for each ball.

The first known attempt at using “shells,” or hollow projectiles filled with explosives, dates from the late 16th century. In theory, when the shell struck the target, the powder inside would be thrown about sufficiently to generate friction against the inside of the shell, in turn generating heat and thereby igniting. In practice, sufficient friction inside the shell occurred as the shell traveled down the barrel to produce ignition before the shell even left the gun.

Just as “buck and ball” loads were used with rifles and muskets, multiple projectile types were used with artillery. In the 15th century “Langridge” – loose metal and stones was often loaded over a wad to give a shotgun effect, and in the 200 or so years before the Revolution, this practice evolved into the two basic groups of scatter projectiles, “case” shot and “grape” shot.

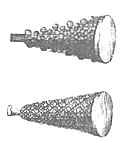

“Canister” and “Case” shot are quite similar – a thin metal cylinder filled with a large number of balls; musket balls in case shot, iron balls in canister shot. The cylinder was affixed to a sabot (from the French word for a wooden shoe) – a thrust-transmitting carrier that prevented the escape of gas ahead of the container. When fired, the outer cylinder was shredded by the shock of the explosion and its shards, along with the balls, were ejected from the muzzle in an expanding cone pattern which had a lethal range of two or three hundred yards.

“Grape” was developed for longer ranges. The container for grape was usually a canvas bag containing lead or iron balls half again as big as musket balls. In order to make such an unwieldy container easier for the gun crew to handle and load, it usually had a wooden base with a center rod extending perpendicularly from it, around which bullets were stacked, and a length of cord would be lashed around it in order to pull the bundle into a manageable shape. The resulting appearance, like a bunch of grapes, gave the type of ammunition its name.

Grape and case used together could create a kill zone of roughly 600 yards, but beyond that enemy troops were fairly safe, except perhaps for the odd projectile striking a soldier or two at such extreme range. In order to save using shells, some odd types of projectile were tried in the hopes of reaping a better harvest.

“Split” shot was two solid half-balls bound together to be loaded as one unit, but to separate after leaving the muzzle and take divergent and unpredictable paths, due to their asymmetry.

“Chain” shot was either split shot or two whole cannonballs connected by a length of chain. On leaving the muzzle the projectile would fly in differing directions until the chain pulled taut, and then the projectile would rotate around its center of mass. Chain was most generally used in naval warfare, since it was perfect for carrying away masts and rigging, but it was also used on land, where its effect on the legs of horses or a massed line of men, was quite effective.

“Bar” shot was similar to chain in design and usage. Two cannonballs, or sometimes two cylinders were attached to one another by a metal bar one or two feet long.

“Hot Shot” was a gun crew’s nightmare. Iron shot would be heated red-hot in a fire, usually in a portable forge that accompanied the artillerists in the field. Then the gun was loaded with a powder charge, and a tight-fitting dry wooden wad rammed on top. This was followed by a wet wad of rags and oakum soaked in water, in order to insulate the powder from the shot during the time the two would be together in the gun. The shot was then brought quickly from the forge, loaded, and fired. Its use was, for obvious reasons, restricted to wooden or other flammable targets, such as ships or gunpowder storage facilities. Perhaps the best known use in the Revolution was an American battery at Yorktown sinking a British warship by a the use of hot shot.

Bronze or iron?

Whether a gun was of bronze or iron governed the weapon’s power.

Iron guns were stronger and therefore could withstand bigger charges of gunpowder; most recommendations for the loading of iron cannon called for a powder charge of one-third the weight of the round shot for the gun. The recommendation for bronze guns was restricted to a charge of only one-quarter of the shot weight. Thus, iron guns could usually achieve a greater range than their equivalent in bronze; an iron six-pounder could fire 1500 yards, while a bronze six-pounder could do 1200 yards.

The advantage of bronze guns was that they were much lighter than their iron equivalents of the same caliber, so that bronze guns were preferred for campaigning, even though the range was less, since they could be moved more easily.

Another advantage of bronze ordnance was that when, eventually, the gun was so worn as to be unserviceable, it could be melted down and recast; wheras an iron gun could only be scrapped.

Last but not least, when cannon were lost at sea, bronze guns were salvagable and almost immediately re-usable, wheras even a short time immersed in sea-water was enough to destroy an iron cannon’s usefulness.

British forces used both bronze and iron artillery pieces, and within each caliber group there were generally a number of variant models. This was simply due to the incredibly long useful life span of a muzzle loading cannon. When a new pattern was approved by the Board of Ordinance, it did not render earlier models obsolete. For instance, in the case of the six-pound cannon (3.66 inch caliber) there were no less than fifteen variations in service; seven iron guns ranging from a six-foot of 16 1/2 hundred weight to a nine-foot of 24 hundredweight; seven bronze guns, from a five-foot of 5 1/2 hundredweight to an eight-foot of 19 1/4 hundredweight; and a carronade, two feet nine inches long weighing 4 3/4 hundredweight. Thus it is necessary to specify the length and weight of any British gun in order to distinguish it from others of similar caliber.

Tools of the trade

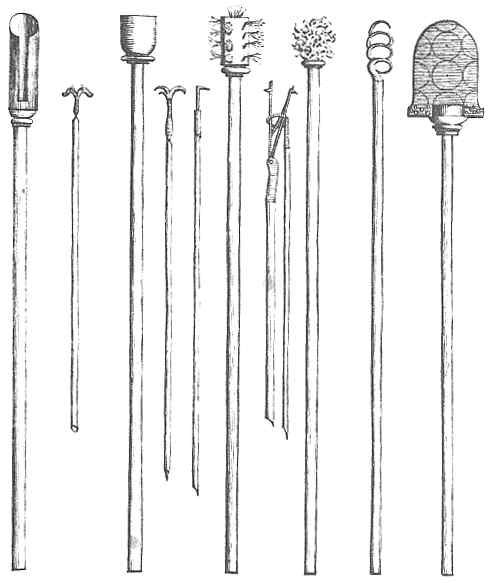

Left to right above:

- A scoop (good for measuring powder or handling “hot shots”).

- A botefeux or linstock, which holds the slow match, which is kept lit to light the portfire or in larger siege guns and on ships, to fire the gun. A portfire is a paper tube with quickmatch in it, held in a wooden handle, lit by the linstock, and which burns like a road flare for several minutes. The portfire will will set a gun off even in the rain.

- A rammer.

- Two priming irons, for clearing the touch-hole and piercing the cartridge.

- A brush.

- A “searcher” to check the interior of the gun for cracks (if caught in a crack, the “reliever” [retractor ring] would be pushed down to compress the prongs and release them from the snag).

- A sponge

- A worm (for removing loads after a misfire)

- A ladle, also for handling both powder and hot shot.

A field guide to setting up and using artillery

To range pieces in a battery, take care to reconnoiter well the ground where it is to be placed, and the road to convey it, in the night time, the cannon and munitions.

The pieces must be armed, each with two lanterns, or ladles, a rammer, a sponge, and two priming irons. The battery must also be provided with carriages, and other implements, necessary to remount the pieces which the enemy should chance to dismount.

To serve expeditiously and safely a piece in a battery, it is necessary to have to each a sack of leather, large enough to contain about twenty pounds of powder to charge the lanterns or ladles, without carrying them to the magazine; and to avoid thereby making those trains of powder in bringing back the lantern from the magazine, and the accidents which frequently happen thereby.

A battery of three pieces must have 30 gabions, because six are employed on each of the two sides or epaulments, which make twelve, and nine for each of the two merlons.

There ought to be two gunners and six soldiers to each piece, and four officers of artillery.

The gunner, posted on the right of the piece, must take care always to have a pouch full of powder, and two priming-irons; his office is to prime the piece, and load it with powder. That on the left fetches the powder from the little magazine, and fills the lantern or ladle which his comrade holds; after which, he minds that the match be very well lighted, and ready to set fire to the piece at the command of the officer.

There must be three soldiers on the right, and three on the left of the piece. The two first to take care to ram and spunge the piece, each on his side. The rammer and spunge must be placed on the left, and the lantern or ladle on the right. After having rammed well the wad put over the powder, and that put over the bullet, they then take each a handspike, which they pass between the foremost spokes of the wheel, the ends whereof will pass under the head of the carriage, to make the wheel turn round, leaning on the other end of the handspike, toward the embrasure.

It is the office of the second soldier on the right, to provide wad, and to put it into the piece, as well over the powder as over the bullet; and that of his comrade on the left, to provide 50 bullets, and every time the piece is to be charged, to fetch one of them and put it into the piece, after the powder has been rammed. Then they both take each a handspike, which they pass under the hind part of the wheel, to push it in battery.

The officer of artillery must take care to have the piece diligently served.

In the night he must employ the gunners and soldiers, who shall relieve those who have served 24 hours to repair the embrasures.

If there be no water near the battery, care must be taken to have a cask filled with it, to dip the sponges in it, and cool the pieces, every ten or twelve rounds.

Before you charge the piece, sponge it well, to clean it of all dirt and filth within-side, then the proper weight of gunpowder, which powder drive in and ram down; taking care that the powder be not bruised in ramming, which weakens its effect; run over it a little quantity of paper, hay, or the like, and then throw in the ball.

To point, level, or direct the piece, so as to play against a certain point, is done by the help of a quadrant with a plummet; which quadrant consists of two branches made of brass or wood; one about a foot long, eight lines broad, and one line in thickness; the other four inches long, and the same thickness and breadth as the former. Between these branches is a quadrant, divided into 90 degrees, beginning from the shorter branch, and furnished with thread and plummet.

Place the longest branch of this instrument into the cannon’s mouth, and elevate or lower it until the thread cuts the degree necessary to hit the proposed object. When done, prime the cannon, and set fire to it.

To point the cannon well, so as to do the execution proposed, we must know the path of a bullet, or the line it describes, from the mouth of the piece to the point where it lodges, which path is commonly called range.

If the piece be laid in a line parallel to the horizon, it is called the right or level range; and if it be mounted to 45 degrees, the ball is said to have the utmost range, and so proportionately; all others between 00 degrees and 45, being called intermediate ranges.

A shot made when the muzzle of a cannon is raised above the horizontal line, and is not designed to shoot directly or point blank, is called random-shot.

The utmost random of any piece is about ten times as far as the bullet will go point blank; and the bullet will go farthest when the piece is mounted to about 45 degrees above the level range.

A 24-pounder may very well fire 90 or 100 shots, every day in summer; at 60 or 75 in winter. In case of necessity, it may fire more. And some French officers of artillery assure, that they have caused such a piece to fire every day 150 shots in a siege.

A 16 and a 12 pounder fire a little more, because they are easier served. There have even been some occasions, where 200 shots have been fired from these pieces, in the space of nine hours, and 138 in the space of five.

Tactical considerations

Tactics tautologically imply movement, and movement was an involved business with the guns of the day. Their speed was the speed of the gunners walking alongside, and once deployed in battle there could be no question of rapid re-deployment to take advantage of a sudden enemy move. Fortunately, the American battles were relatively small affairs by European standards, and once the guns were positioned they could generally command the more important sectors of the field without having to redeploy.

When setting up forces for a battle, all the available guns would usually be arranged into a “Grand Battery” deployed in the center of the line of battle. An alternative would be to place individual gun companies at intervals between the formed infantry battalions. Light guns (up to 12 pounders and 5.5″ howitzers) were assigned in pairs to infantry regiments as regimental guns, and moved with them or in advance of the infantry to lay down covering fire until the enemy was in musket shot range.

The guns could then open the battle by bombarding the enemy infantry, cavalry or the enemy guns; it was a gamit worthy of a chess master. If you chose to open fire on the enemy infantry and/or cavalry, while his guns opened fire on your artillery, you ran the risk that your guns would suffer heavy casualties. On the other hand, if you chose to batter the enemy guns while the enemy guns zeroed in on your infantry and/or cavalry, your guns could be left defenseless if your infantry/cavalry withdrew rather than take heavy casualties, or your entire line could be overrun more easily by an intact enemy force on the charge. And if the opposing batteries hammered at each other, they could be criticized for ignoring the remainder of the opposing forces, which would eventually decide the day between themselves, and the artillery would have been superfluous to the battle.

Artillery could fire up to 4 times per minute moving and faster when stationary, limited by the stamina of the crew and the available ammunition. The gunners achieved this speed by carrying fixed rounds with projectile, sabot and powder fixed together.

Due to the limited field of kill of the round shot of the day, a common tactic was to deploy the guns to the flanks of the intended battlefield. Theoretically, the line formation of the enemy would coincide sooner or later with the line of fire of the guns, and great devastation would be inflicted when the enemy were “taken in enfilade”. There is a case on record of 42 men being scythed down like wheat by a single ball which took their line in enfilade.

Once battle had been joined and the infantry began to advance, the artillery batteries were at a disadvantage. They could not move with the advance, and they were unable to go on firing once they were masked by the movement of their own troops. Techniques of indirect fire, over the heads of their own infantry into the ranks of the enemy, were some years in the future. The subsequent activities of the guns depended on the course of the infantry battle; the guns of the victors were limbered up and moved on, while those of the vanquished were overrun by the enemy advance, since they could rarely be brought out of action quickly enough to save them from capture. Guns changed hands frequently during a campaign, and the loss of guns was considered a normal hazard of battle and did not carry the stigma it was to gain a few years later when lighter ordnance and better horse teams made the saving of guns a more likely proposition

One contemporary document specifies the optimum elevation of a gun as four degrees. Obviously, four degrees doesn’t strike one as very much elevation, and it would be reasonable to assume that by increasing the elevation more range would have been achieved. Theoretically, this is quite true, but it was never put into practice for a number of reasons. In the first place a greater elevation meant a correspondingly steeper angle of arrival at the target, and a steeply-descending cannon ball simply buried itself in the ground. A ball fired at a lesser elevation arrived at a flatter angle, was dangerous to standing troops for a greater distance at the end of its flight, and then ricocheted and skipped across the ground haphazardly, making the enemy step very lively in all sorts of unpredictable directions.

Colonial iron

The demand for Iron products in the North American colonies was at first satisfied by importing from Britain. There were many iron works in production in Pennsylvania and in other colonies as early as 1740’s. With a few as early as the 17th century. But as vast iron deposits were discovered in the colonies and ironworks established, the colonies began to export bar and pig iron to England, as well as supply American markets in sufficient quantities to compete seriously with British imports. So much so that Parliament passed the Iron Act of 1750, restricting colonial ironworks to the prodution of bar and pig. But the Act was honored much more in the breach rather than the observance, as confirmed by the variety of products supplied to local markets by forges and furnaces. Even the Royal Governors found profit by looking the other way at the iron works in their colonies. Domestic iron production was widespread during the several decades prior to the Revolution, much of it being initiated and conducted on behalf of investors from Great Britain.

It has been estimated that as of 1775, what would become the United States was producing one-seventh of the world’s iron.

While Washington saw holding the Hudson Highlands as crucial from a geographic standpoint, there was another important consideration. The entire region of the Hudson Highlands, stretching west from Danbury CT, crossing to the west shore of the Hudson and south to Pompton NJ was heavily mineralized with iron ore. Prior to the war, the man who would become Washington’s chief of mapmaking for the army, Robert Erskine, was employed as manager of the Ringwood Furnace (NJ) which had operated for a number of years before 1775. A bit south was the Charlottenburg Furnace, named for a now-extinct town of that name just north of Pompton. Within close proximity to West Point was the Deane (or Dean) Furnace, just about five miles west of Forts Montgomery and Clinton. In fact, several of Washington’s daily General Orders during the summer of 1779 refer to units being rotated to more foreward position at “the furnace” (then already abandoned as to operation) from the Smith’s Clove camps of the VA, MD and PA Lines. References to the “furnace road” also appear within the spy reports Beverly Robinson prepared for Clinton in the latter’s planning of the October 1777 invasion and reduction of Forts Montgomery and Clinton.

One of the largest iron production facilities of the colonial period was the Batsto Furnace in the “pine barrens” area of southern NJ. The site has become an educational tourism site and presents a great deal of informaton on colonial period iron foundry operations.

Gunpowder

Roger Bacon, in his Epistolae de Secretis Operibus describes gunpowder, and gives a description of how to make it, but the actual invention remains shrouded in the mists of history. Chemically, gunpowder is a “mixture.” That is to say, the ingredients do not bond together on an atomic or molecular level, but are simply mechanically combined.

The ingredients are saltpeter, sulphur, and charcoal, in equal parts by weight (more saltpeter in the mixture will produce powder for muskets, even more will give you pistol powder.) These ingredients are moistened to avoid sparks,and the mixture is then ground between the great stone wheels of a powder mill, similar to grinding grain into coarse flour. The resulting mixture is then moistened into a paste, and pushed through a sieve, a process known as corning the powder, to produce small grains, the size and shape of which determine the quality of the powder. If you’ve ever seen a colonial powder mill, you’ve no doubt noticed it was situated far from any habitation, and surrounded by a high dirt berm, for obvious reasons.

For most of the 18th century and well into the 19th, the world saw an “arms race” to develop a better gunpowder. One of the important needs of the Continentals was an adequate domestic supply of saltpeter and a satisfactory grade of gunpowder. The defects of the powder made in the United States were well known to the scientists of the day, and the military forces had difficulty when impurities that absorbed moisture from the air itself made it all but impossible to “keep your powder dry.”

This question was indeed one of international importance. The best powder was Swiss, having the most uniform grain. In 1776 France selected M. Lavoisier to be superintendent of the National Powder Works. Coleman was investigating the properties of charcoal in England, and thanks to his research, British powder was of superior quality. Bowles, Dillon, and Townshend had studied the Spanish niter deposits, and the Indian supply was also the subject of investigation. The Second Continental Congress encouraged the manufacture of saltpeter by offering twenty pounds for every hundred-weight made.

France conducted extensive tests in the arsenal at Essonne in 1756 to produce a superior powder. To test the samples, they used an éprouvette, a mortar with a bore of 7 inches, to hurl a 60 lb copper sphere using 3 ounces of powder. To pass the testing, a powder had to hurl the sphere 50 toise (300 feet). Around this general time frame, the British Royal Board of Ordnance bought a powder mill near Faversham in Kent. Both the quality and quantity of the gunpowder supplied to the British Army and Navy suffered as a result. During the five years prior to government ownership the Faversham mill produced 7,144 barrels of gunpowder of which roughly 5,787 barrels met government proof standards. In the following five years under government ownership production dropped to only 6,973 barrels of gunpowder, of which only 4,463 barrels met the standards. Doing the math, this is a loss of 1,324 barrels of proofed powder production during the five years that Board of Ordnance had owned and operated the Faversham mill.

While the operation of the Faversham mill did little to either improve the quality of powder being produced nor reduce the government’s need for civilian manufacturers. It did indicate that the Board of Ordnance had mismanaged the operation of the Faversham mill.

There may also have been other factors at play in the manufacturing operations at Faversham, as a number of powdermakers, acting as a political lobby, were attempting to persuade Prime Minister William Pitt to coerce the Board of Ordnance into selling the Faversham mill.

After the Revolution, none other than William Congreve, developer of the “Congreve Rocket”, famous as in “the rocket’s red glare” and as the great grand-daddy of todays space vehicles, was selected to conduct an investigation into the quality of British gunpowder. He began conducting a broad series of tests using a barrel of virtually every type of gunpowder that he could find. Each sample was carefully tested for proof and then the sample barrels were sent on board HMS GRAMPUS for a voyage to the West Indies and back. The barrels of gunpowder were then reexamined and tested for proof. Despite the claims made by British civilian manufacturers their samples fared no better than the ones provided by the Faversham mill, all were found to be spoiled. The civilian gunpowder had turned into large unusable lumps which constituted from 27 to 90 percent of the contents of the barrels. Overall Congreve indicated that this would have amounted to a serviceability rate of about 60 percent. What makes the GRAMPUS testing all the more interesting is that the samples from Sweden, Russia and Holland were all undisturbed by the voyage with the grains remaining separate and serviceable. Thus, the problem was narrowed down to the British manufacturing process. As Congreve put it, British powder produced a “rotton grain”.

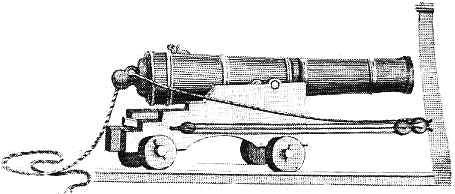

Carriages

Early in the war, most American artillery was commandeered from ships and forts. These would have been mounted on ship or garrison carriages (above). These were simply stout wooden frames that rested on four small wheels called “trucks.” The cannon rested between the sides of the frame on cross-members called “transoms,” and the sides had depressions on top to accommodate the trunnions of the gun.

These were fine on a ship, where lateral re-deployment was done by changing the direction of the ship, and in a fort, where a cannon has a specific field of fire. But for fighting battles, a gun first has to get to the battle over roads with ridges and ruts, then it has to negotiate the uneven terrain of the battlefield itself. this type of movement called for wagon wheels and an axle with a high ground clearance. Thus, the ship and garrison carriages had to be converted by carpenters and wheelwrights into field carriages, either the block trail or the flask type.

A block trail carriage had the trailing unit formed of a single piece of timber. While this was sufficient for lighter guns, heavier guns were necessarily mounted on flask trails, made of two side pieces with the gun between them (above).

Another indispensable piece of transport equipment, used for hauling heavy guns over long distances, was the sling cart (above).

Most carriages were made of oak, but walnut, chestnut and maple were also used. The wheels were constructed of either elm or beech. The carriages were a variety of colors including gray, rust, white, and dark blue. In 1780, Washington ordered all carriages painted a light blue in honor of France, light blue being the French royal color.

Knox – The Indispensable Artilleryman

American Artillery grew out of a small number of militia artillery companies in the Colonies. When war came, the members of these companies brought to the Patriot cause their expertise and their guns. Foremost among these was Henry Knox, a Boston bookseller, volunteer artilleryman and self-taught military genius, who took charge of the foundling American artillery branch and whipped it into a formidable force, probably the most effective branch of the Continental Army.

The first units to be formed were independent companies from the various colonies, such as Lamb’s New York Artillery Company, the Rhode Island Train of Artillery, etc. But Knox was wide awake to the drawbacks of parochialism and in mid-1776 he re-organized the forces into four regiments of Continental Artillery. Originally, his establishment called for three regiments of twelve companies and one of eight, but this was later changed to a standard ten-company regiment. The companies varied in strength, depending upon what caliber of guns they possessed and how many of them, the usual gun strength being six to ten guns or howitzers per company.

The available guns were truly a hodge-podge. In the beginning, the ordnance consisted of whatever could be “liberated” before the British Army came along and removed them – obsolete cannons from coast batteries, hand-me-down guns of volunteer companies and ship cannons. The motley collection consisted of three-pounder to 24-pounder guns, with the larger calibers most numerous. As a result of this imbalance, and because it was inevitable that this small stock of ordnance would be insufficient, gunfounding was begun in various places. The first to be produced were small one- and two-pounder swivel guns for naval use, but once the techniques had been mastered larger weapons were made. In 1776 some sixty 12-pounders and 18-pounders were cast in Pennsylvania, and shortly afterwards a standardized four-pounder light field gun was put into production.

This is where the genius of Henry Knox came to the fore. Instead of having cannons of all sorts and dimensions cast all over the place, he pressed for the concentration of manufacturing effort in one place, where it could be controlled, supervised, and simplified, and he selected Springfield, Mass., as the gunmaking center. Knox was confident that the British commanders would neither appreciate the significance of Springfield nor, if they did, be capable of carrying out an operation against the town.

American-manufactured guns were largely copies of British standard models, since these were the easiest to obtain for the preparation of patterns. A few were constructed on the lines advocated by John Muller, who was the Professor of Artillery and Fortification at the Royal Academy, Woolwich. His book, “A Treatise of Artillery,” was published in 1756 and was the standard text of the day, and a pirate copy was published in Philadelphia in 1779, which became the handbook of the American artillerymen. In this book, Muller had published plans of a cannon based on sundry theories of his own, and as a result, the few cannons that were ever built according to Muller’s ideas were made in America. You can tell an American cast tube by looking for a liberty cap on a pole and a sunburst design cast into the metal. The letters “U.S.” or “U.C.” for United Colonies also appear on some guns.

To convey an idea of the complexity of the American artillery train, here is Knox’s requests for artillery for 1778: Brigade artillery, 17 brigades, with four guns each: – 68 pieces to be 3, 4, or 6 pounders; with the park – two 24-pounders, four 12-pounders, four 8-inch howitzers, eight 5 1/2 -inch howitzers, ten 3 or 4 pounders, ten 6-pounders, for reserve, to be kept at a proper distance from the camp, thirty 3, 4, and 6-pounders, two 12-pounders, one 24-pounder, all the foregoing brigade, park , and reserve guns and howitzers to be brass. In addition, twelve 18-pounders, twelve 12-pounders, battering pieces, on traveling carriages, together with two 5 1/2 -inch and twelve 8, 9, and 10 inch mortars; the battering pieces and mortars to be cast in iron.

The French supplied thirty-one 4-pounders which Knox found very useful as field pieces. These were of the Swedish design. They also sent other guns of the Valliere system in the four pound size. These guns Knox found to be so heavy and over cast that he had them melted down and recast into light 6-pounders. Each four-pounder made three light 6-pounders.

PERSONNEL

Prior to the Revolution, guns were actually operated in battle by soldiers, but they were transported by civilian teamsters and carters working on contracts. And as they were not slow to point out, their contracts were solely to move guns to and from the scene of action, and didn’t extend to risking their lives under enemy fire. As a result, the first people to make themselves scarce when the bullets began to fly were the artillery teamsters, taking their precious horses with them, and if the hard-pressed gunners needed to move their guns there was no means of doing so other than manpower.

This problem of civilian teamsters was one which afflicted every army of the age, since owners of armies were reluctant to foot the bill, in peacetime, for a host of non-combatants.

During the Revolution both the British and American artillery relied upon contract teamsters for movement, but for the British, with a limited amount of horseflesh available, and with contractors reluctant to ally themselves with the Redcoats, much of the transportation capacity had to be shipped across the Atlantic. On the other hand the American teamsters, while distinct from the Army, still had a fellow-feeling for “their” soldiers and were more inclined to risk their lives and those of their horses for the “cause”.

After the Revolution, more and more armies began to reorganize their artillery to do away with the contractor and bring the entire force into uniform.

Matrosses first appeared on the establishment (in the British Army) in 1639. Originally, they were Gunners Assistants, i.e., the “servitor Gunners” or “inferior Gunners” of former years upgraded and given a more respectable title. Unlike their predecessors they were all on the same rate of pay, somewhat lower than the Gunner’s.

The word comes from the German “matrossen,” meaning “sailors,” since the tasks allotted them in action, such as traversing, loading, firing, sponging, manning dragropes, etc, were deemed to be sailors’ work. They were less highly trained technically than Gunners.

Matrosses were armed with muskets and bayonets, as their duties included guarding the guns and wagons on the march, as well as assisting when breakdowns occurred. Later they also took over from the Fusiliers the job of preventing the Drivers running away when the shooting started.

In 1783 the rank of Matross was abolished in the British Army, all serving Matrosses being elevated to the rank of Gunner. They had earned it, for their record was no less distinguished than that of Gunners, as the following story typifies: During the Siege of Gibraltar by the Spanish (1779-83) a shell penetrated the hospital near where a matross lay injured, and bursting near him took off both his legs. Before he died in great pain he uttered no word except to express his regret that he had not been hit while in action on the gun position.

The Fog of War

“Fog of War” is a term often encountered in military writings even to the present day. In the 18th century, it had a specific meaning that is almost incomprehensible to people in the 21st century.

To illustrate, the series of photographs below demonstrate the amount of particulate matter generated by the discharge of a small cannon.

Now, try to envision the amount of smoke that would be generated by dozens of pieces of artillery on a field of battle. Add to that the gunsmoke generated by hundreds, or even thousands, of muskets firing in volleys (below).

Now, envision generals and their staffs on the nearby high ground, trying to follow the movements of the troop formations on the field below, and you can grasp the meaning of the “Fog of War.”

Recommended Further Reading

Arms Collecting, a quarterly journal, suspended after forty years. In back issues, you will find technical/historical articles, less than monograph length. One example; the proper dating of Muller’s Treatise of Artillery was reported here. I have found them immensely valuable and you might scan the issue indexes to find technical/historical papers on obscure issues, e.g. Royal Artillery gun sledges in early 19th century Canada.

Bartenstein, Fred, and Isabel Bartenstein. New Jersey’s Revolutionary War Powder Mill. Mendham, N.J.: Privately printed, 1973.

Biever, Dale E. “Ordnance at Hopewell Furnace.” Military Collector and Historian, 23 (Winter 1971).

Birkhimer, William E. Historical Sketch of the Organization, Administration, Materiel and Tactics of the Artillery, United States Army. Washington: James J. Chapman, 1884.

Boatner, Mark M. Encyclopedia of the American Revolution. NY: McKay, 1966.

Borresen, Thor; Spanish Guns and Carriages 1686-1800, ms., Yorktown, 1938.

Boyer, Charles S. Early Forges and Furnaces in New Jersey. Philadelphia: University of Pennsylvania Press, 1931.

Brewington, M. V. “American Naval Guns, 1775-1785.” American Neptune, 3 (January, April 1943).

Brooks, Noah. Henry Knox, a Soldier of the Revolution; Major-General in the Continental Army, Washington’s Chief of Artillery, First Secretary of War Under the Constitution, Founder of the Society of the Cincinnati; 1750-1806. New York: G. P. Putnam’s Sons, 1900.

Callahan, North. Henry Knox, General Washington’s General. South Brunswick, NY: Barnes, 1958.

Cippola, Carlo M. Guns, Sails and Empires: Technological Innovation and the Early Phases of European Expansion 1400-1700. New Haven: Pantheon Books, 1965.

Calvert, Monte A. “The Search for a Domestic Source of Saltpeter for Use in Making Gunpowder, 1620-1920.” Master’s Thesis, University of Delaware, 1961.

Caruana, Adrian B. Grasshoppers and Butterflies: The Light 3 Pounders of Pattison and Townshend. Bloomfield, Ont.: Museum Restoration Service, 1979.

Caruana, Adrian B. The History of English Sea Ordnance, 1523-1875; Volume II , The Age of the System, 1715-1815. Jean Boudriot Publications, Rotherfield, England, 1997. (The Royal Navy absorbed about ninety percent of the production of the British Board of Ordnance and Carauana provides important detail on the sucessive developments in the casting of iron ordnance as well as related technical details.)

de Beer, Carel, editor: The Art of Gunfounding: The Casting of Bronze Cannon in the late 18th Century. Jean Boudriot Publications, Rotherfield, England, 1991. This is a major expansion of an earlier work, cited frequently, by Dr. Melvin Jackson of the Smithsonian and de Beer, published as, Eighteenth Century Gunfounding. It contains the story of the Verbruggens at Woolwich. The additional material includes fifty Foundry Drawings by the Verbruggens (watercolors, reproduced here in color), part of Traite’ d’Artillerie by David Emannuel Musly and The Founding of Bronze Guns -1793, by Isaac Landsman, Professor, Woolwich. A list of surviving Verbruggens is included.

de Morla, Tomás; Laminas pertenecientes al Tratado de Artillería, Madrid, 1803.

de Saint-Remy, M. Surirey; Memories d’Artillerie, 3rd edition, Paris, 1745.

Downey, Fairfax. “‘No Artillery Better Served’: The Beginnings of U.S. Artillery – Trenton, Princeton and Monmouth Court House.” Army Combat Forces Jrnl 6 (Sep 1955)

Downey, Fairfax. “Birth of the Continental Artillery.” Military Collector and Historian, 7 (Fall 1955).

Evans, Robert M. “The King of Battle: Ruler of Yorktown.” Field Arty Jrnl 49 (Sep – Oct 1981): pp. 30-31.

Ffoulkes, Charles J.; The Gunfounders of England; Cambridge, 1937

Fredrick, John. “Firing the Molly Stark.” Army 29 (July 1979): pp. 25-28. Rev War cannon still fired periodically at New Boston, NH.

Gooding, S. James; Museum Restoration Service (Bloomfield, Ontario) publications; www.armscollecting.com . Now semi-retired, he began in the 1960’s publishing numbered limited edition museum quality reprints of key 18th century works, mostly artillery. Those numbered edition reprints are now, mostly if not all, out of print but sometimes turn up on the internet. One example: An Introduction to British Artillery in North America, 1965.

Graves, Donald E. ed.; DeScheel’s Treatise On Artillery, Translated by Jonathan Willams (and printed for the War Office, Philadelphia, 1800.) Reprinted.

Gruber, Ira D. “British Strategy: The Theory and Practice of Eighteenth-Century Warfare.” In Don Higginbotham, editor, Reconsiderations on the Revolutionary War: Selected Essays (Westport, Conn.: Greenwood Press, 1978).

Hall, A. R. Ballistics in the Seventeenth Century: A Study in the Relations of Science and War with Reference Principally to England. Cambridge: Cambridge University Press, 1952.

Hamilton, Edward P. “Colonial and Revolutionary Artillery.” Bulletin of the Fort Ticonderoga Museum, 12 (December 1969).

Handwork, Edna M. “First In Iron, Berks County’s Iron Industry 1716 to 1815.” Historical Review of Berks County, 25 (Fall 1960).

Hecht, Arthur. “Lead Production in Virginia during the Seventeenth and Eighteenth Century.” West Virginia History, 25 (April 1964).

Hicks, James E. Notes on French Ordnance, 1717 to 1936. Mt. Vernon, N.Y.: Privately printed, 1938.

Historical Arms Series (HAS) of readable/technical monographs. Caruana’s Grasshopper and Butterflies is now in this series having been restyled from the larger technical monograph format. Other HAS titles include Caruana’s The Light 6-Pdr. Battalion Gun of 1776; 72 pages, much of which is direct from the Woolwich Archives; essential for the reenactor. And, S. James Gooding’s, An Introduction to British Artillery in North America, 54 pp. There are many titles in the Historical Arms Series covering a wide spectrum of 18th century weaponry in North America.

Holst, Donald W. “Further Notes on the King Howitzer.” Military Collector and Historian, 38 (Winter 1987).

Holst, Donald W. “The Use of Carronades During the American Revolution.” Military Collector and Historian, 40 (Winter 1988).

Holst, Donald W. “Continental Light Artillery, 1781.” Military Collector and Historian, 41 (Summer 1989).

Hughes, B. P. British Smooth-Bore Artillery: The Muzzle Loading Artillery of the 18th and 19th Centuries. London: Arms and Armour Press, 1968.

Hughes, B. P. “Firepower in the Smooth-Bore Period.” Proceedings of the Royal Artillery Historical Society, (January 1975).

Jones, James T., and John R. Elting. “The Regiment of Artillery Artificers (Flower’s Artillery Regiment), 1777-1783.” Military Collector and Historian, 27 (Summer 1975).

Jones, James T., and John R. Elting. “Rhode Island Train of Artillery (‘The United Train of Artillery’)–1775.” Military Collector and Historian, 26 (Summer 1974).

Jones, James T., and John R. Elting. “Continental Artillery, 1776-1783.” Military Collector and Historian, 28 (Spring 1976) Military Collector & Historian is the journal of the Company of Military Historians; their website is www.military-historians.org

Manucy, Albert; Artillery Through the Ages, a Short Illustrated History of Cannon, Emphasizing Types Used in America. National Park service Interpretative Series, 1949 (reprinted 1962.)

McAfee, Michael J. Artillery in the American Revolution. Washington: American Defense Preparedness Association, 1974.

McBarron, H. Charles, Jr.; Marko Zlatich; and James L. Kochan. “2nd Continental Artillery Regiment, 1781-1783.” Military Collector and Historian, 43 (Spring 1991). Military Collector & Historian is the journal of the Company of Military Historians; their website is, www.military-historians.org

McConnell, David; British Smooth-Bore Artillery: a Technological Study; 595 pages of text, period drawings, photos sources. The most important broad reference work available; not a survey. Parks Canada, 1988. Also printed in French for Quebec.

McMaster, Fitzhugh. “Colonial Cannon: South Carolina Artillery 1670-1813.” Field Artillery Journal, 45 (September-October 1977).

Mauncy, Albert. Artillery Through the Ages: A Short Illustrated History of Cannon, Emphasizing Types Used in America. Washington: National Park Service, 1949.

Middlebrook, Louis F. Salisbury Connecticut Cannon. Salem, Mass.: Newcomb & Gauss Co., 1935.

MRS published lengthy monographs, e.g. Elementary Treatise on the Forms of Cannon & Various Systems of Artillery, Translated for the use of the Cadets of the U.S. Military Acadeny from the French of Professor N. Persy of Metz, 1832; MRS, 979. And, British Artillery Ammuntion: 1780, by Adrian B. Caruana.; MRS, 1979.

Muller, John. A Treatise of Artillery: Containing General Constructions of Brass and Iron Guns used by Sea and Land, and their Carriages, General Constructions of Mortars and Howitzers, their Beds and Carriages… London: Millan, 1780; orig pub 1757 and reprinted 1779. 208 p.

Nelson, William. “Beginnings of the Iron Industry in Trenton, New Jersey.” Pennsylvania Magazine of History and Biography, 35 (1911).

Neu, Irene D. “The Iron Plantations of Colonial New York.” New York History, 33 (January 1952).

Neumann, George C. The History of Weapons of the American Revolution. New York: Harper and Row, 1967.

Paret, Peter. “Colonial Experience and European Military Reform at the End of the Eighteenth Century.” Institute of Historical Research Bulletin, 37 (May 1964).

Paret, Peter. “The Relationship Between the Revolutionary War and European Military Thought and Practice in the Second Half of the Eighteenth Century.” In Don Higginbotham, editor, Reconsiderations on the Revolutionary War: Selected Essays (Wesport, Conn.: Greenwood Press, 1978).

Partington, J. R. “A History of Greek Fire and Gunpowder.” 1960.

Peterson, Harold L. Round Shot and Rammers. Harrisburg, PA: Stackpole, 1969.

Ransom, James M. Vanishing Ironworks of the Ramapos: The Story of the Forges, Furnaces, and Mines of the New Jersey-New York Border Area. New Brunswick: Rutgers University Press, 1966.

Rudyerd; Course of Artillery at the Royal Military Academy As Established By His Grace the Duke of Richmond Master General of His Majes’ys Ordnance, 1793, C.W. Rudyerd, 1793. Rudyerd was a Woolwich cadet and this is the drafting book required of each cadet who would carry this book with him around the world so he could direct the construction of carriages, etc. This book is the original source of the drawings which you encounter in so many different places. This a gem and a priority purchase.

Salay, David Lewis. “The Production of Gunpowder in Pennsylvania During the American Revolution.” Pennsylvania Magazine of History and Biography, 99 (October 1975).

Seidel, John Lewis. “The Archaeology of the American Revolution: A Reappraisal and Case Study at the Continental Artillery Cantonment of 1778-1779, Pluckemin, New Jersey.” Ph.D. Dissertation, University of Pennsylvania, 1987.

Smith, Charles C. “The Manufacture of Gunpowder in America.” Proceedings of the Massachusetts Historical Society, 14 (March 1876).

Stephenson, Orlando W. “The Supply of Gunpowder in 1776.” American Historical Review, 30 (January 1925).

Stevens, P.H. Artillery Through the Ages. Franklin Watts, Inc., New York, NY,1965.

Strach, Steven G. A History of the Three Pound Verbruggen Gun and Its Use in North America 1775-1783

Tucker, Spencer C. “Cannon Founders of the American Revolution.” National Defense, 60 (July-August 1975).

Weller, Jac. “Guns of Destiny: Field Artillery in the Trenton-Princeton Campaign, 25 Dec 1776 to 3 Jan 1777.” Mil Affairs 20 (Spring 1956)

Weller, Jac. “The Artillery of the American Revolution.” Military Collector and Historian, 8 (Fall-Winter 1956). Military Collector & Historian is the journal of the Company of Military Historians; their website is, www.military-historians.org

Weller, Jac. “Revolutionary War Artillery in the South.” Georgia Historical Quarterly, 46 (September-December 1962)

Wickstrand, Norman M. “Notes and Sketches of Connecticut Blast Furnaces.” Connecticut Historical Society Bulletin, 51 (Summer 1986).

Wintringham, Thomas H. The Story of Weapons and Tactics from Troy to Stalingrad. Boston: Houghton-Mifflin Co., 1943.

York, Neil Longley. Mechanical Metamorphosis: Technological Change in Revolutionary America. Westport: Greenwood Press, 1985.

York, Neil Longley. “Technology in Revolutionary America, 1760-1790.” Ph.D. Dissertation, University of California at Santa Barbara, 1978.